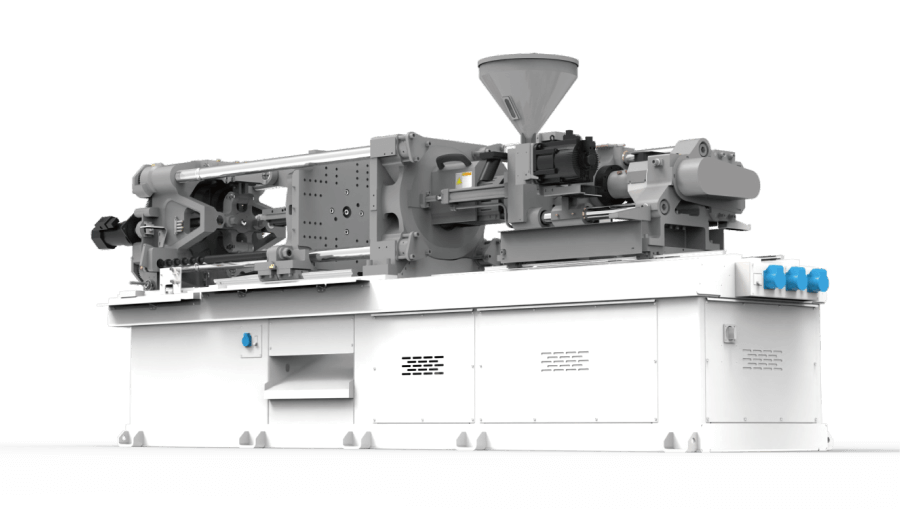

The new EH Series is the latest addition to the Spark Family. Setting the highest standards in the realm of all-electric performance, the EH Series harmoniously unites the best of two worlds: electric and hydraulic. It marks the advent of next-generation all-electrics, making them available to you today.

Reap the benefits of both electric and hydraulic drive trains for additional applicability without sacrificing precision and performance.

Reap the benefits of both electric and hydraulic drive trains for additional applicability without sacrificing precision and performance.

Stability and repeatability at high speed for even the most demanding applications.

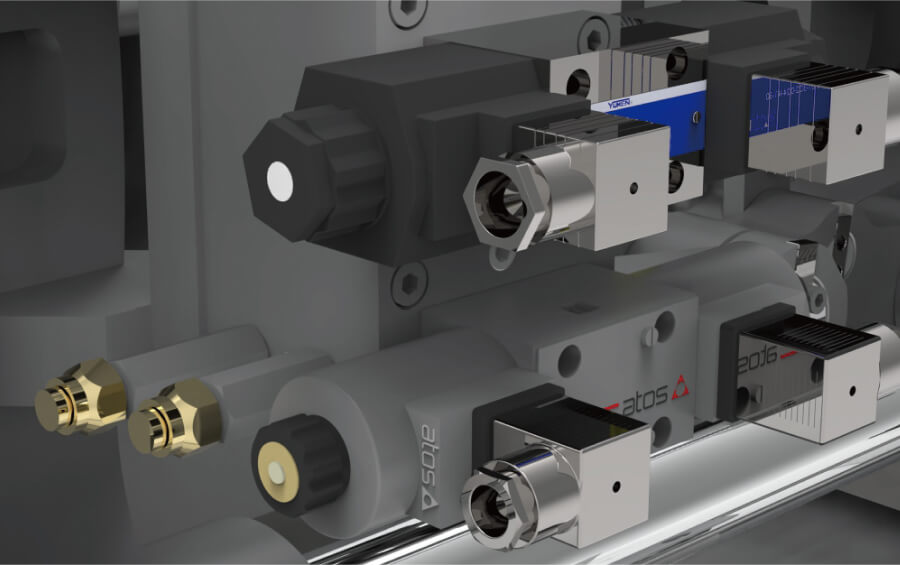

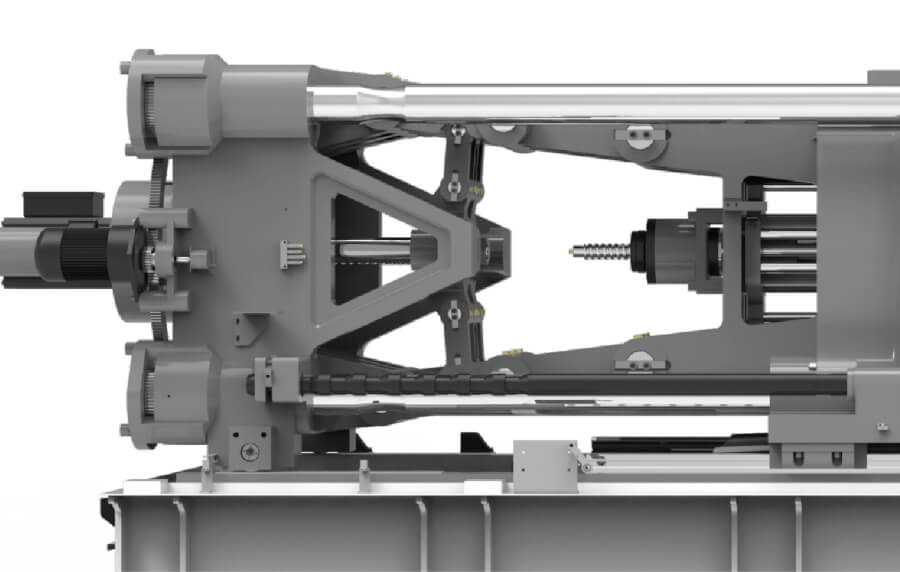

SPARK EH Series efficiently combines electric and hydraulic drive trains. The precision and performance of electric drives govern the overall operations, while the power and flexibility of hydraulics are harnessed for core pulling. With the EH Series, you get the best of both worlds, ensuring uncompromised power and control.

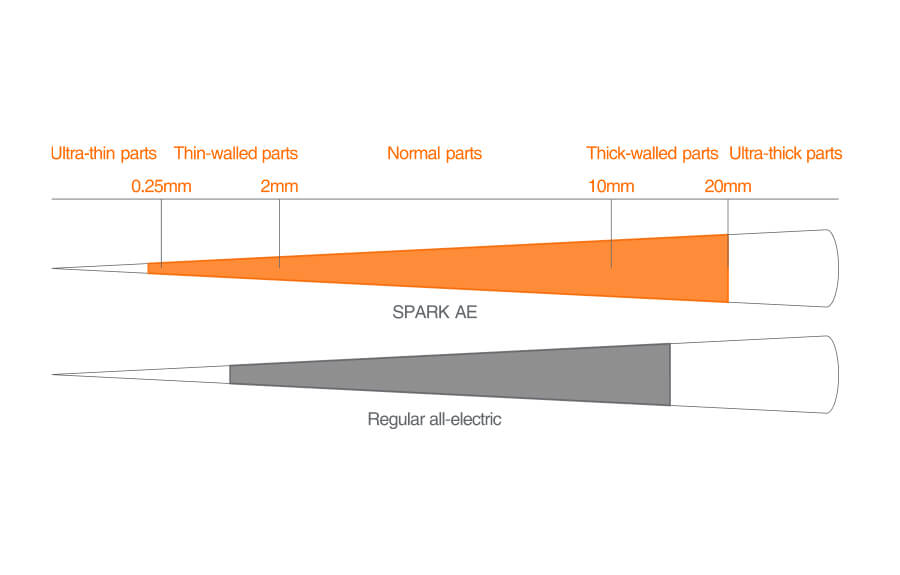

One machine to make them all – from ultra-thin parts requiring ultra-fast speed and responses, to ultra-thick parts demanding rock-solid stability under low-speed and prolonged high-pressure conditions.

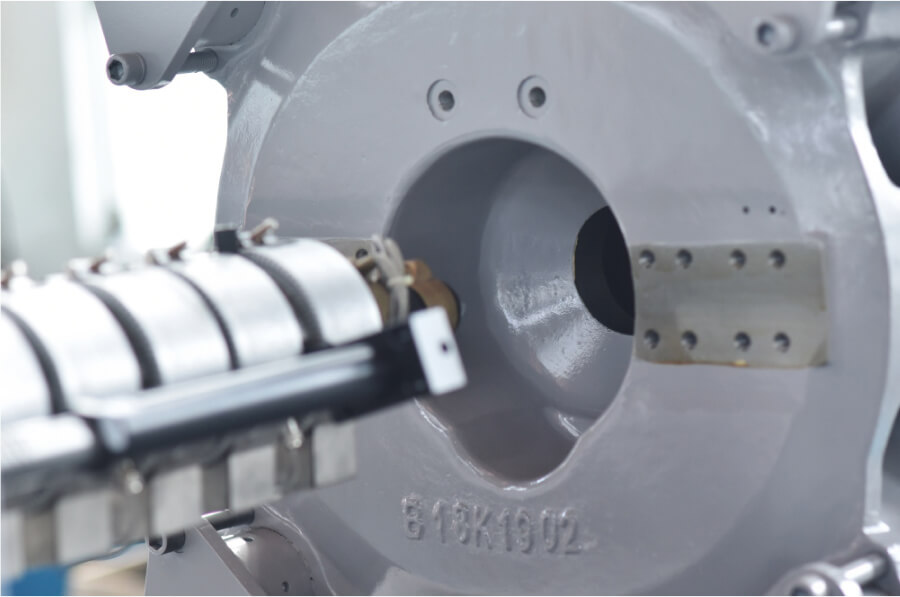

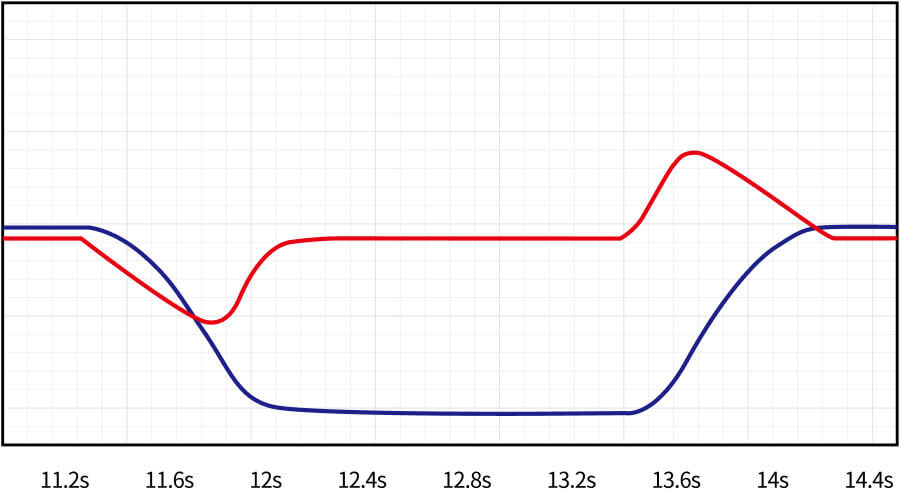

Auto Stress Release System (ASRS) is a revolutionary technology that, again, employs high-speed computer algorithms that dynamically monitors via high-speed digital pressure transducers, the actual motion of the injection screw (<1ms scan time).

Then computer controller makes real-time adjustments to the motion of the screw when detecting motions that may lead to accumulation of internal stresses on the part – typically the No.1 enemy of high yields and the No.1 reason for rejects.

Marriage of a proprietary ultra-high-response servo system with very-high-speed advanced computer control, yielding no-compromise levels of responsiveness — from zero to 2000 rpm in less than 30 ms! That is ten times faster than traditional all-electric machines (300 ms) in the China market!

15″ touch-screen, easy-to-use HMI with user-friendly UI – power at your fingertips.

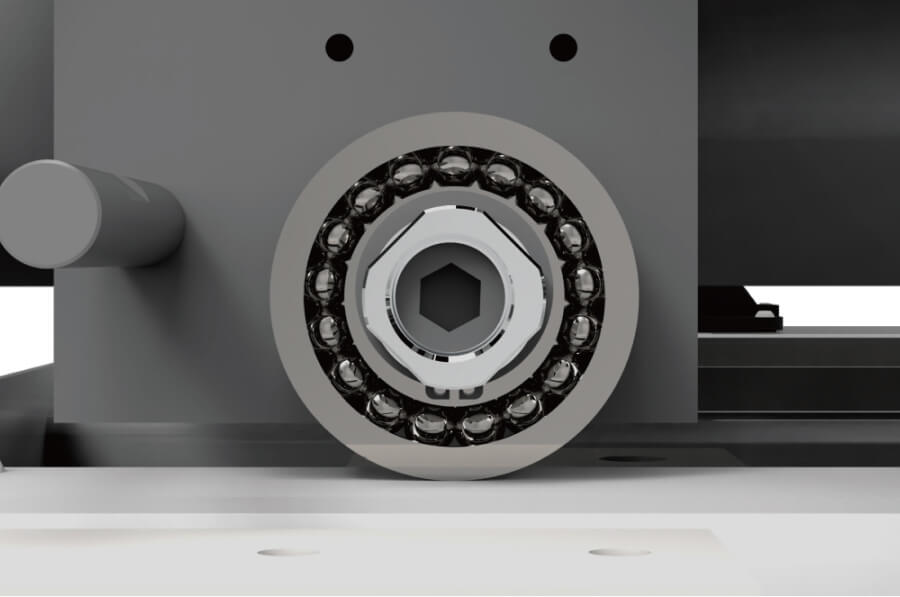

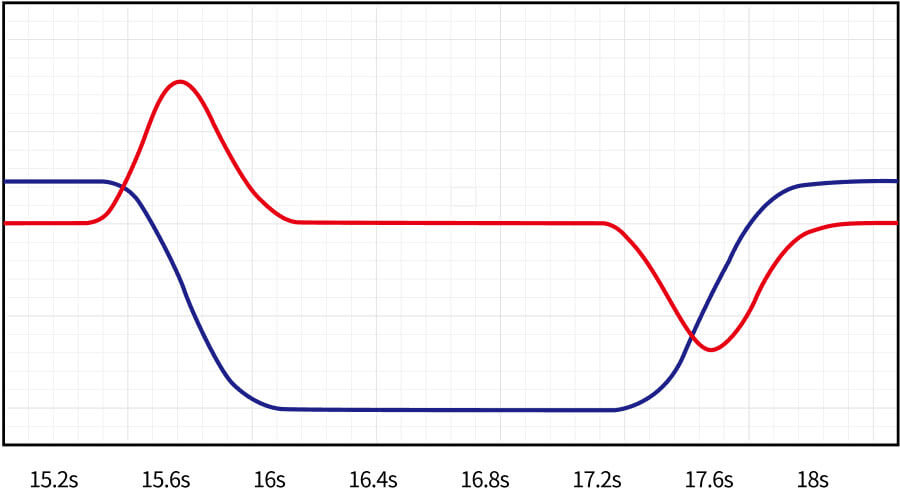

Algorithmic Cross-Protection (AxP) is based on high-end electronics, fine-tuned mechanical design and high-speed computer algorithms, it provides total protection to the mould during high-speed clamp closing by monitoring and adjusting, in real-time, the dynamical motions of the clamping ball-screw.

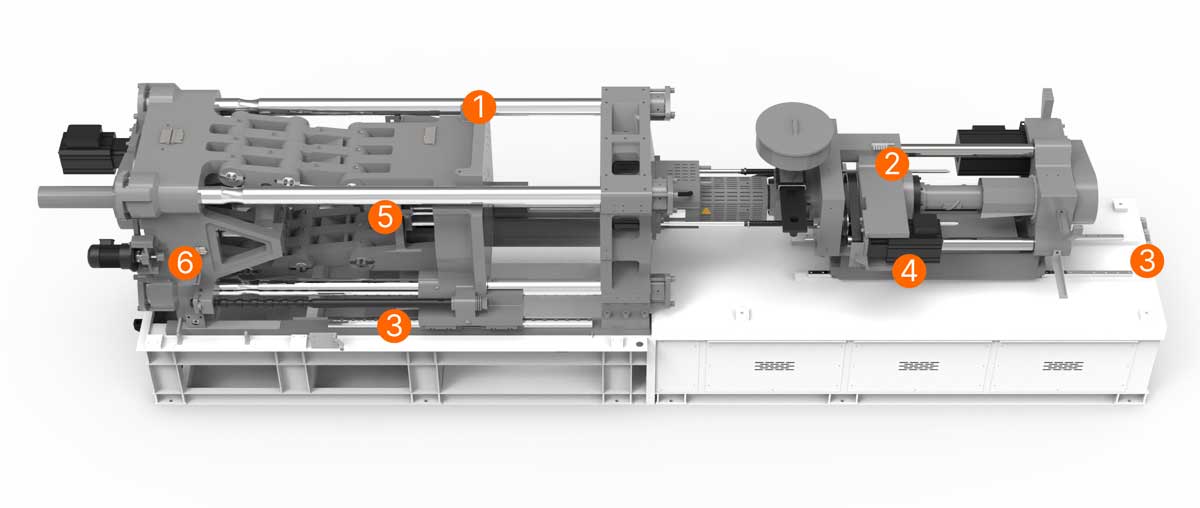

Patented Circular Platen design and High-strength Machine Base Designed In Japan ensure even stress distribution and low deformations for higher quality parts and superior dimensional stability. The Tail Platen Adjustment Mechanism offers high stability with low friction.

Tail Platen Adjustment Mechanism for Low friction and high stability

High-strength Machine Base Designed in Japan

Tie-bars are detached from the moving platen, eliminating friction and noise

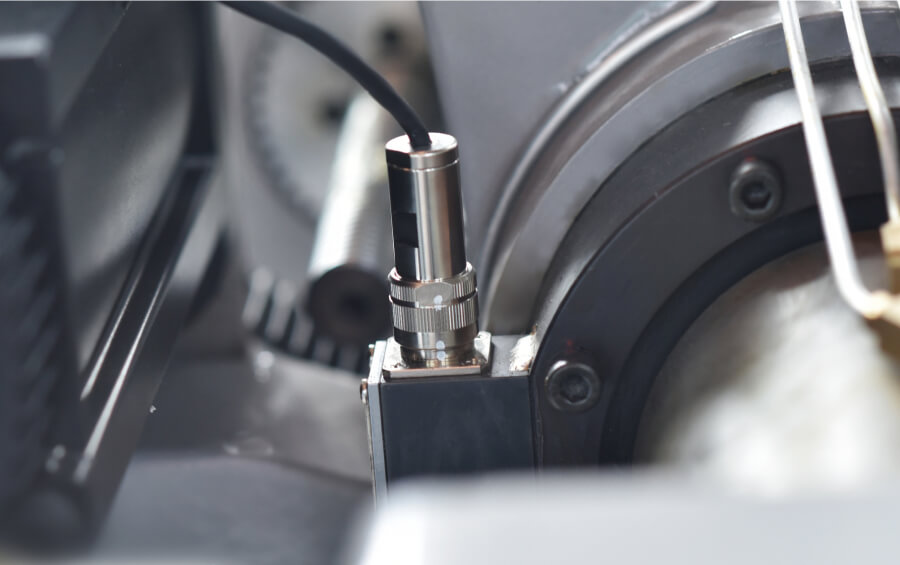

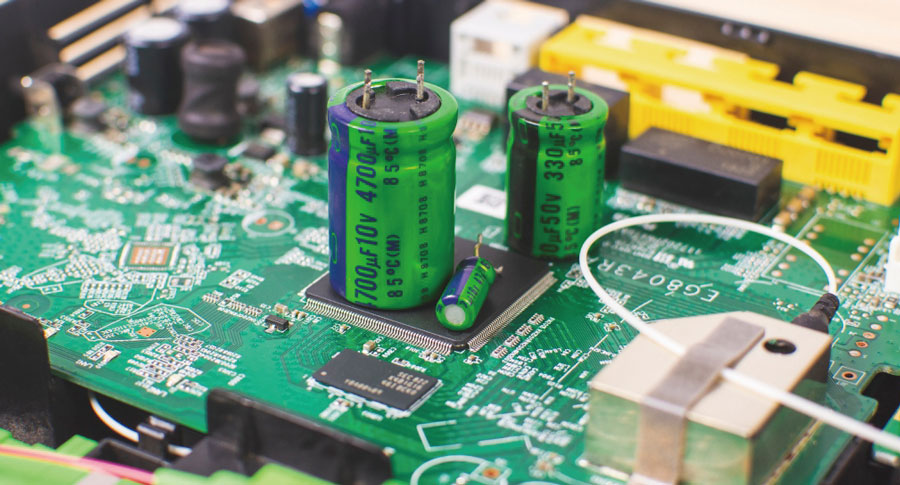

Named-brand high-precision pressure transducers ensure the finest performance and protection levels

High-precision linear guide rails

for injection and clamping units

Specialty-developed IPM servomotor with fast response, large torque, low noise and mild temperature profile

Euromap-style ejector support, wide applicability for different moulds

Centralised automatic lubrication system.

No manual control needed. No mistakes.

No wastage. Fit for clean-room environments

SPARK EH Series

0.22kWh/kg

Regular 100T

0.25kWh/kg

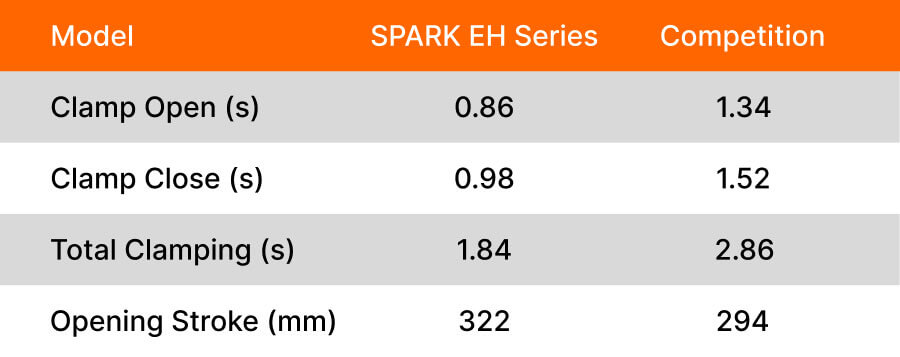

more power efficient (and thus less cost to run) than regular competition offerings for the same productivity.

SPARK EH Series

63.5dB

Regular 100T

67.5dB

Our patented platen design, paired with a low-noise servo system and advanced control algorithms, delivers silky-smooth motion. This makes our offering not only quieter but also greener than competing alternatives.

High-end linear guide rails for moving platen

No linear guide rails

We value your feedback! If you have a specific question or inquiry, or just want to let us know how we are doing, please complete the form below. We’ll get back to you as soon as possible.

Stay in touch and get the latest from CH India. Stay informed with product updates, launches, news, trade shows and much more.

North:

New Delhi

Ghaziabad

Gurgaon

Rajasthan/Bhiwadi

West:

Navi Mumbai

Mumbai

Bhosari

Chakan

Maharashtra/Aurangabad

South:

Tamil Nadu / Chennai

Tamil Nadu/ Coimbatore

Karnataka /Bengaluru

Tamil Nadu / Hosur

Choose Your Region

The Chen Hsong Group has offices and distributors all around the globe.

Select your region from below or search our global list of distributors.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

|

|

Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |