Tailored specifically to Indian industrial needs, the Mk6.6/SI-“SI” standing for “Superior India”-is a new jewel in Chen Hsong’s crown. It’s the product of more than three decades of our meticulous work in India, a testament to our deep understanding of the region’s unique needs and priorities. This machine is much more than a tool; it’s a tailor-made solution, crafted to perfectly fit the Indian manufacturing landscape.

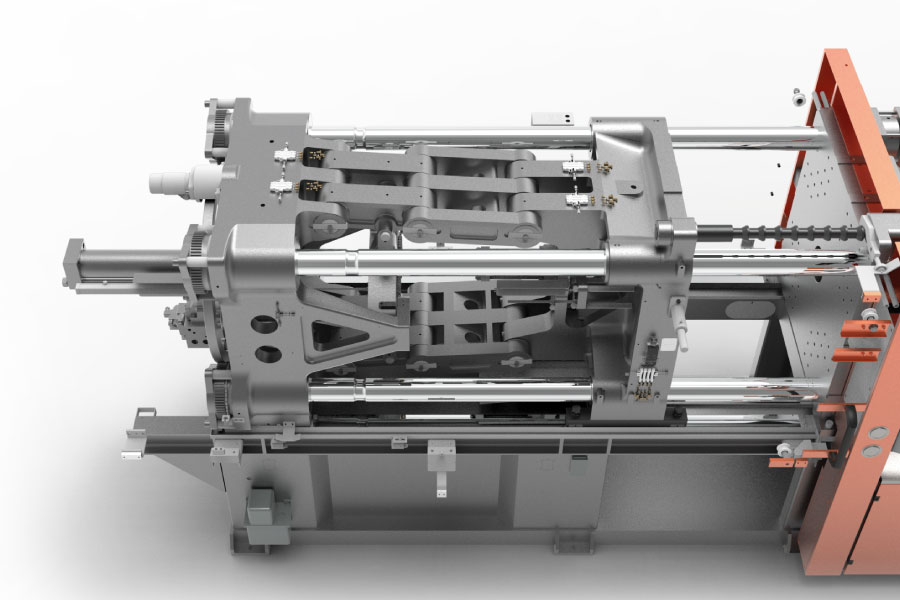

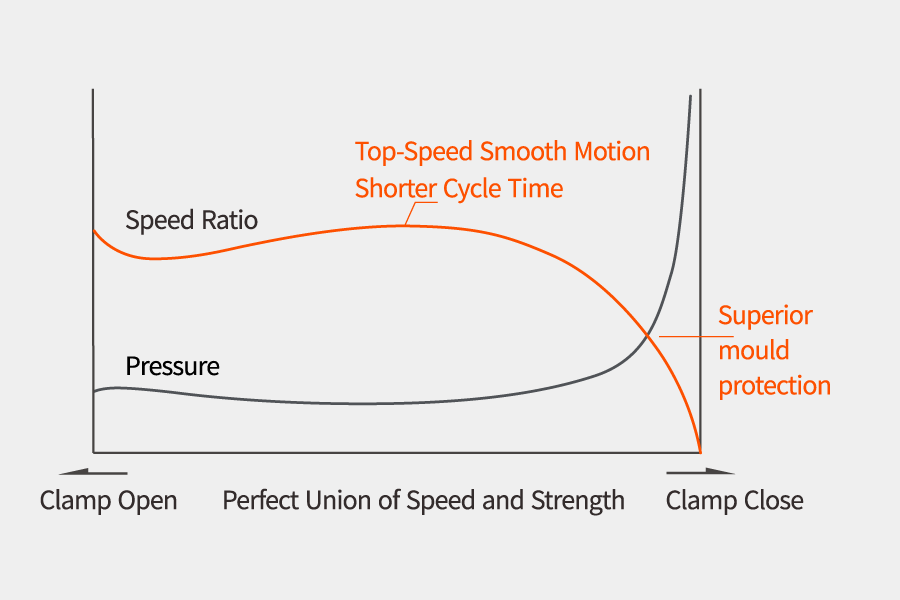

The Mk6.6/SI leverages 65 years of Chen Hsong’s pioneering experience in injection moulding, honed by the latest technological advancements and merged seamlessly with proprietary Japanese Precision Hydraulics™ technology. The outcome is an equipment capable of silky smooth, high-speed motion, setting new industry benchmarks for speed, stability, and reliability.

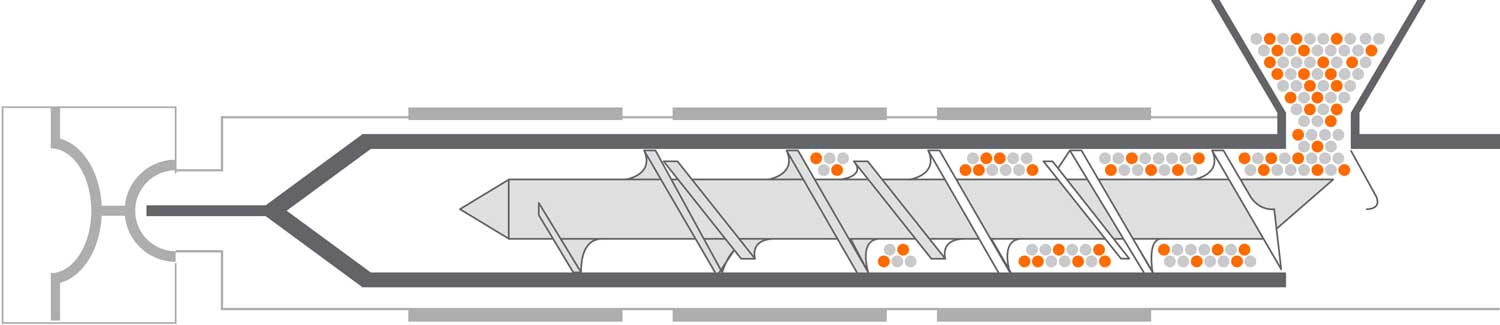

The ‘SI’ series’ key feature is its precision linear guideway in the injection unit. This innovation boosts moulding accuracy, cuts cycle times, improves load management, and augments rigidity, while reducing maintenance demands. Altogether, it significantly enhances performance and reliability.

The CPC6.6 leverages the ITRON industrial-grade hard-real-time OS, commonly used in hig h-end Japanese machine tools for extremely high repeatability and short reaction times.

LED lighting part

Shot Weight : 121g

Cavities: 8

Resin : PC

Cycle Time : 32.4s

Mould

Weight : 350kg

Dimensions : 400mmx400mmx300cmm

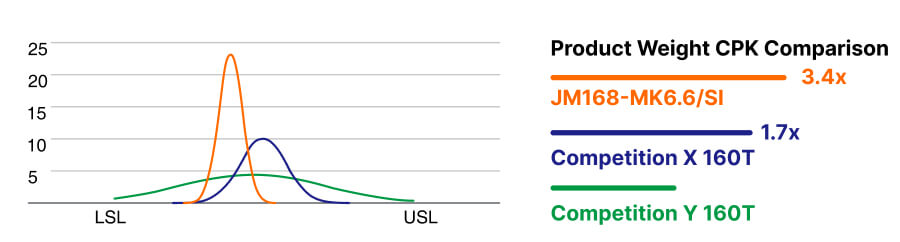

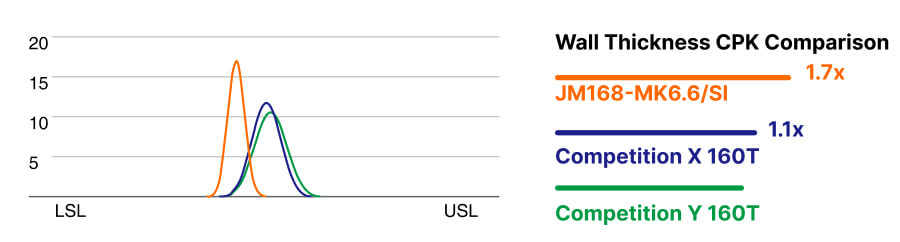

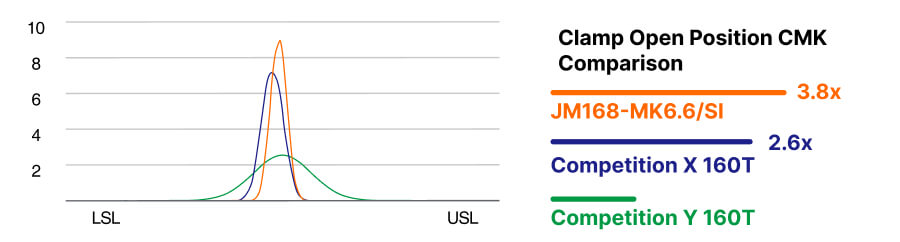

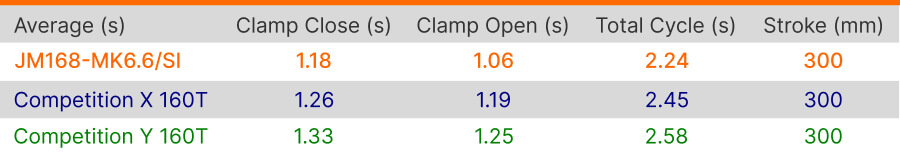

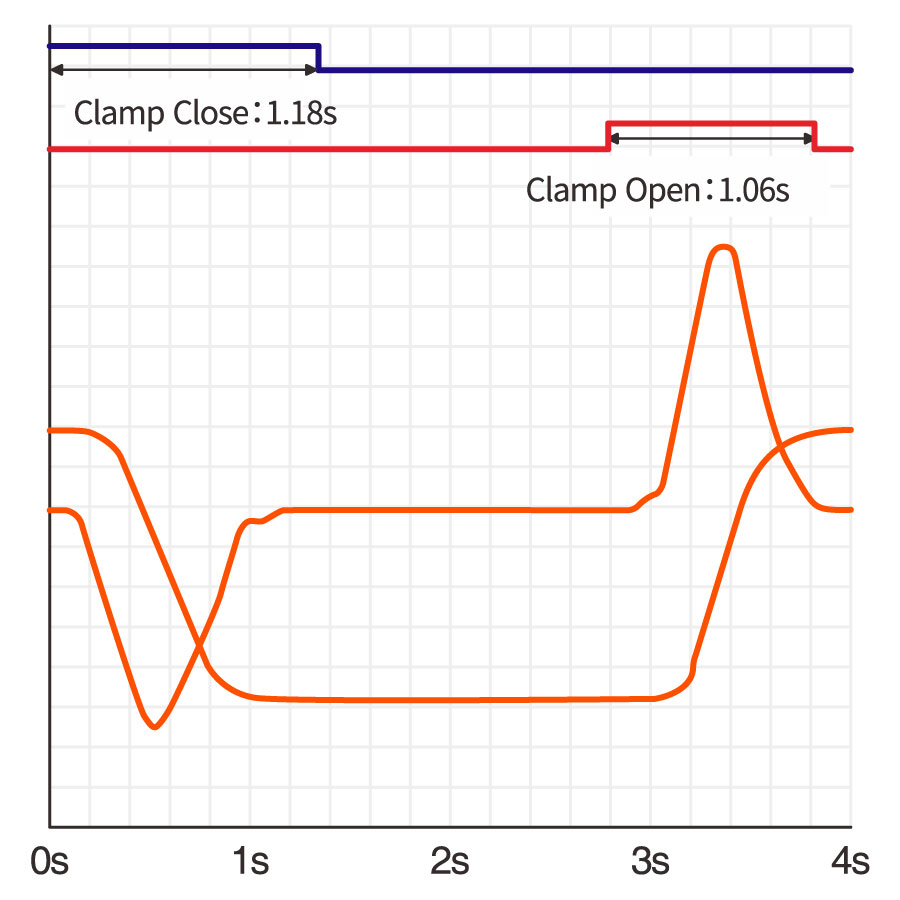

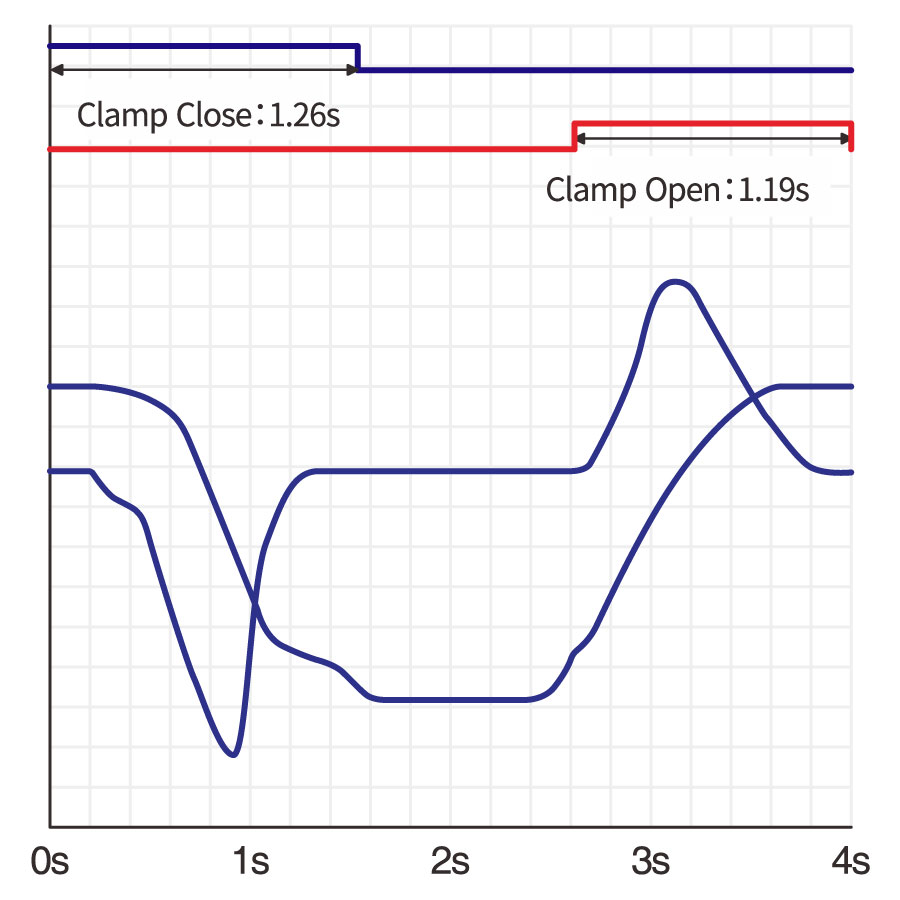

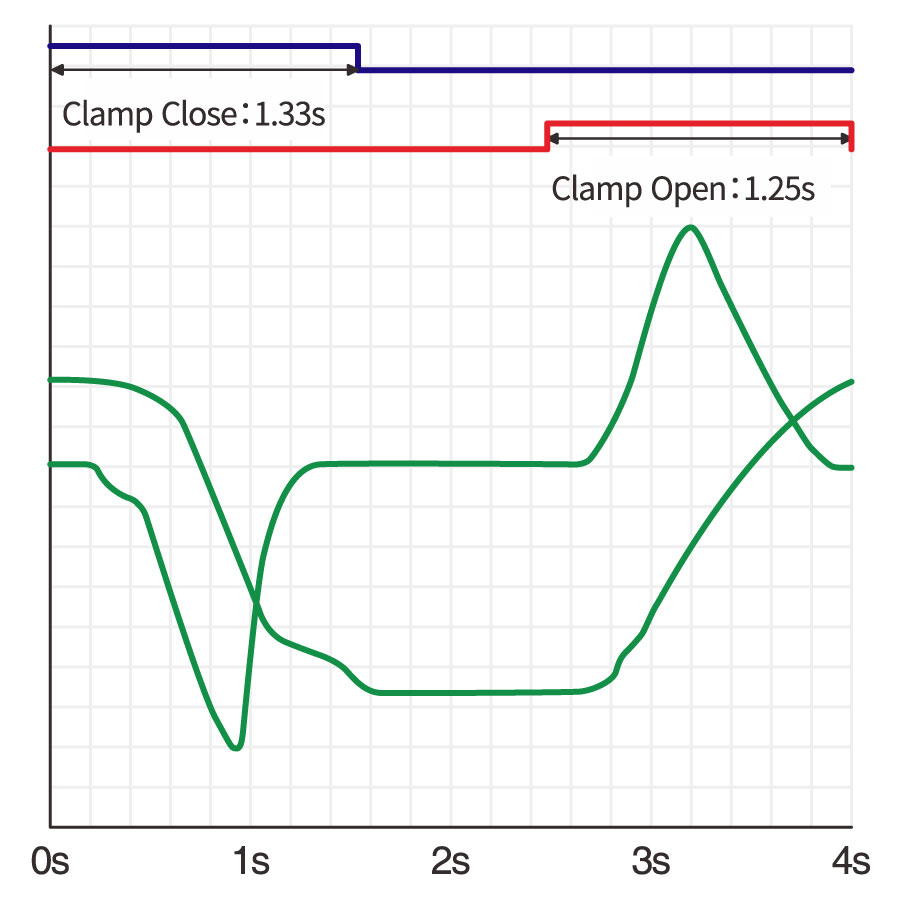

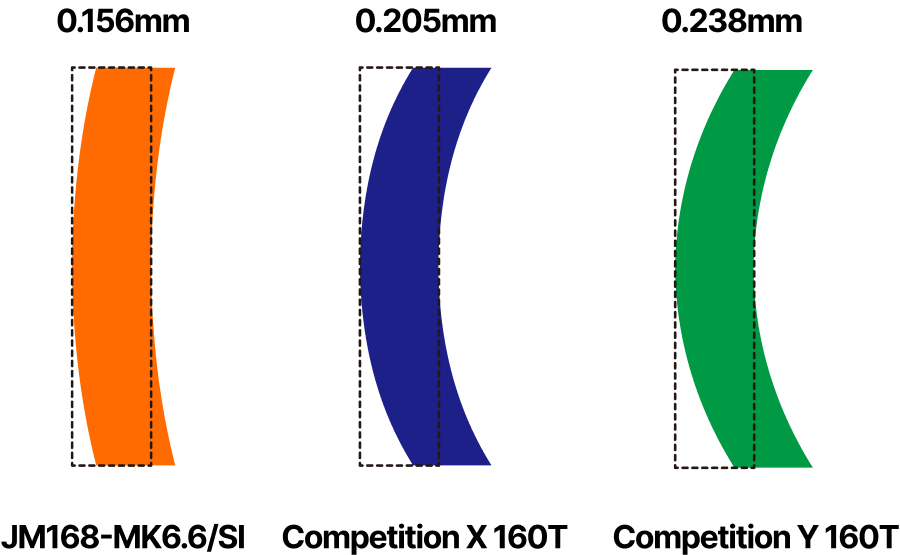

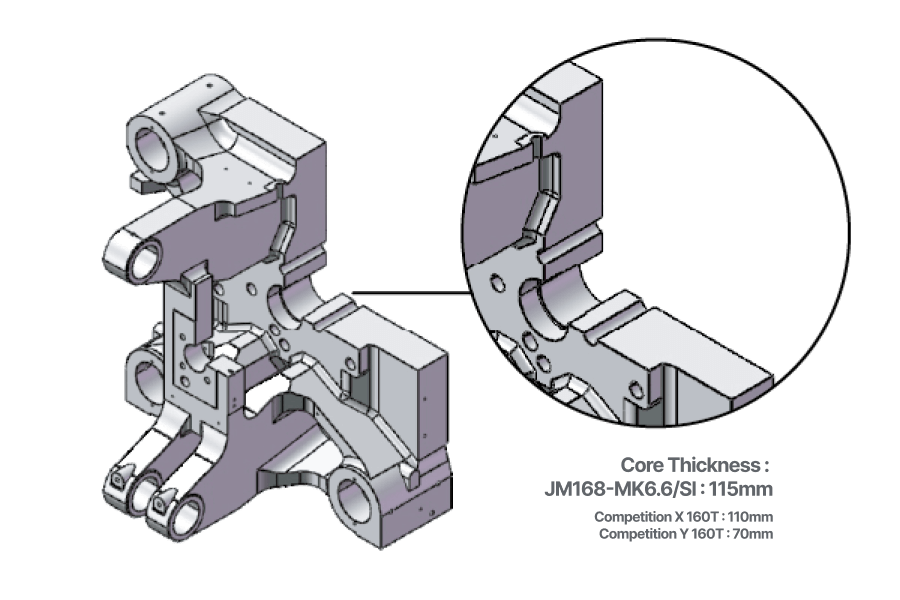

JM168-MK6.6/SI

Competition X 160T

Competition Y 160T

We value your feedback! If you have a specific question or inquiry, or just want to let us know how we are doing, please complete the form below. We’ll get back to you as soon as possible.

Stay in touch and get the latest from CH India. Stay informed with product updates, launches, news, trade shows and much more.

North:

New Delhi

Ghaziabad

Gurgaon

Rajasthan/Bhiwadi

West:

Navi Mumbai

Mumbai

Bhosari

Chakan

Maharashtra/Aurangabad

South:

Tamil Nadu / Chennai

Tamil Nadu/ Coimbatore

Karnataka /Bengaluru

Tamil Nadu / Hosur

Choose Your Region

The Chen Hsong Group has offices and distributors all around the globe.

Select your region from below or search our global list of distributors.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

|

|

Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |