The secret ingredient behind this unbelievable performance is Precision Hydraulicstm technology – a Japanese-based technological revolution that achieves unprecedented pre-cise and accurate motion control at the highest operating speeds. The result is performance, reliability and stability infinitely close to Japanese-standard injection moulding machines, operating at 300-500mm/s injection and as short as a 1.5-second dry cycle.

“Brains over Brawn” – Precision HydraulicsTM is a revolutionary technology developed by senior Japanese engineers over many years of intensive research. It employs the latest in software simulation technology and the most updated control theory to all but eliminate unnecessary pressure drops, yielding a hydraulic circuit that is highly optimised, virtually shock-free, and smooth as silk. A machine equipped with Precision Hydraulicstm technology can easily match the performance of a Japanese-standard injection moulding machine costing double or triple the price.

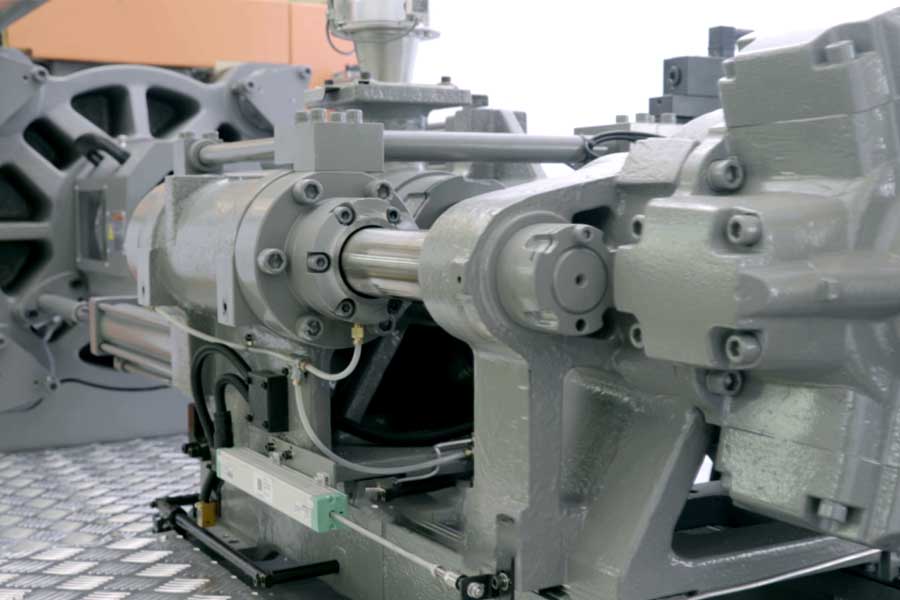

Standard injection unit is specially optimised for high-speed applications with higher injection speeds and pressure.

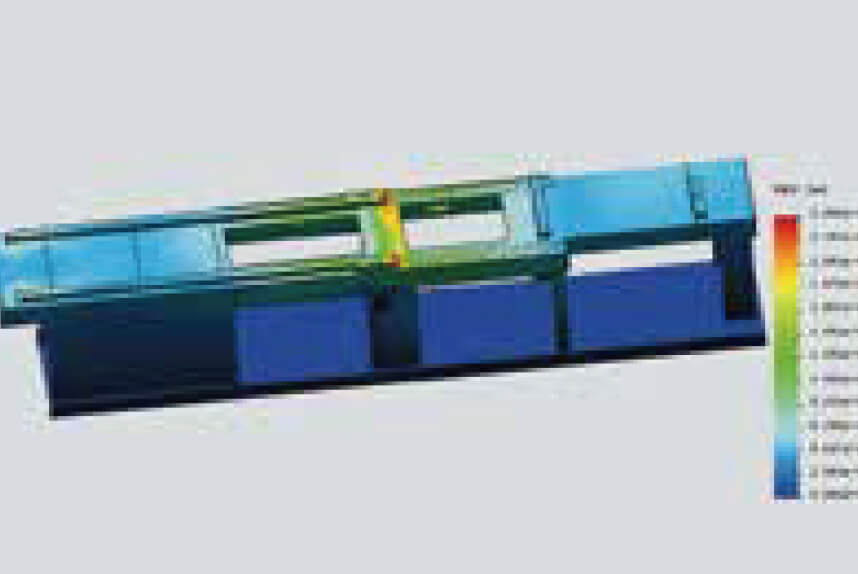

Optimised platen design distributes stresses

evenly for higher part quality

Designed to match the unique require-ments of ultra-high-speed motion curves,the machine base is specially designed to enhance structural strength, rigidity and stability by 50%, thus ensuring the highest part quality.

Stress is channelled through the centre of the moving platen before distributing outwards evenly. Advanced Japanese mechanical design guarantees perfect alignment of the four corners at all moments, effec-tively eliminating flashes.

Self-lubricating bushings have no need for lubricating oil while providing superior lubrication day in and day out, reducing unnecessary wear. Result is less pollution, less wear, less costs. Everyone wins.

Faster responses for higher repeatability, control precision and energy efficiency

Non-contact potentiometers for the highest accuracy during high-speed injection; Eliminates wear and interfer-ences for ultimate stability

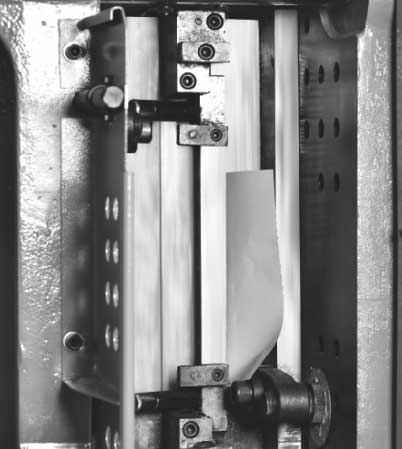

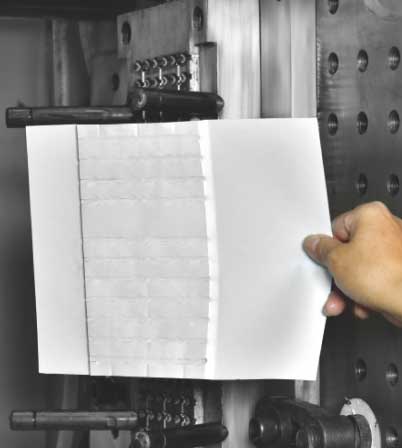

High-precision linear potentiometers are used for the clamping, injection and ejector axes which, when combined with highly-optimised algorithms, enable superior low-pressure mould protection – effective even with obstacles thinner than 0.1mm (or the thickness of a sheet of paper)!

Before clamp close, put in a sheet of standard A4 paper

Almost closing, detecting paper

Low-pressure mould protection causes clamp to open

A4 paper is not even punctured through!

We value your feedback! If you have a specific question or inquiry, or just want to let us know how we are doing, please complete the form below. We’ll get back to you as soon as possible.

Stay in touch and get the latest from CH India. Stay informed with product updates, launches, news, trade shows and much more.

North:

New Delhi

Ghaziabad

Gurgaon

Rajasthan/Bhiwadi

West:

Navi Mumbai

Mumbai

Bhosari

Chakan

Maharashtra/Aurangabad

South:

Tamil Nadu / Chennai

Tamil Nadu/ Coimbatore

Karnataka /Bengaluru

Tamil Nadu / Hosur

Choose Your Region

The Chen Hsong Group has offices and distributors all around the globe.

Select your region from below or search our global list of distributors.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

|

|

Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |