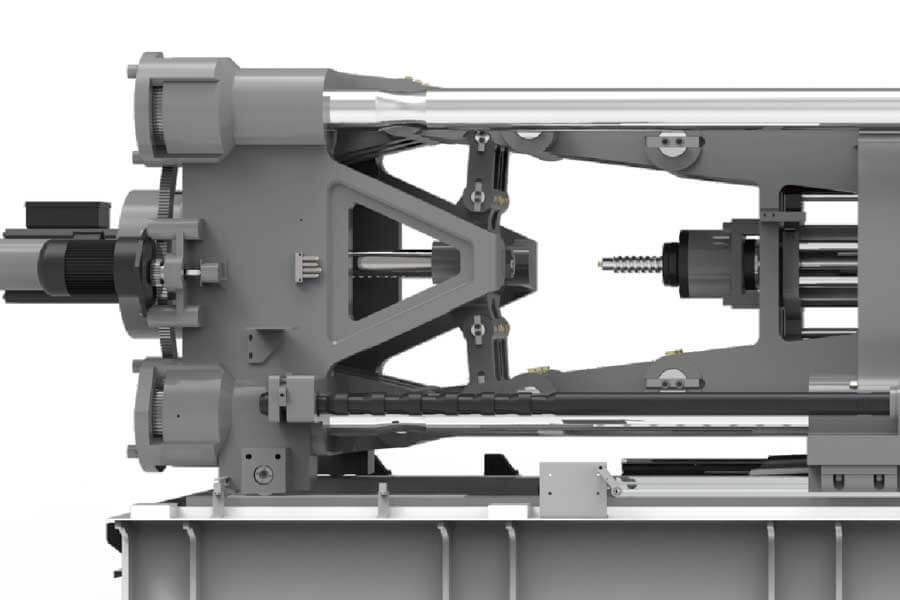

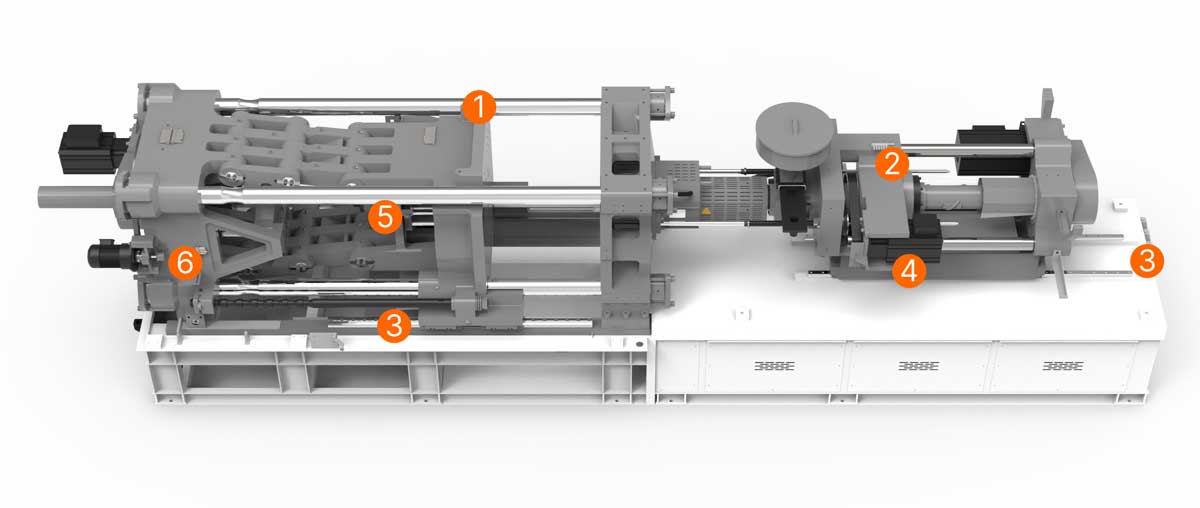

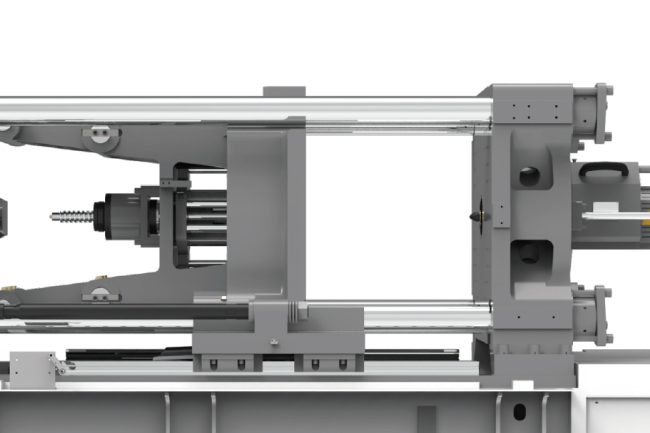

Tie-bars are detached from the moving platen, eliminating friction and noise

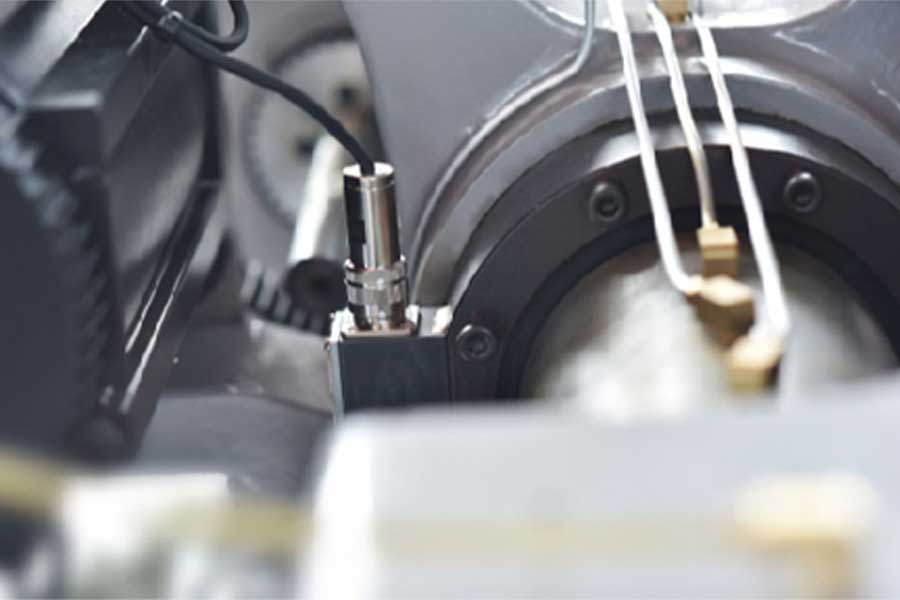

Named-brand high-precision pressure transducers ensure the finest performance and protection levels

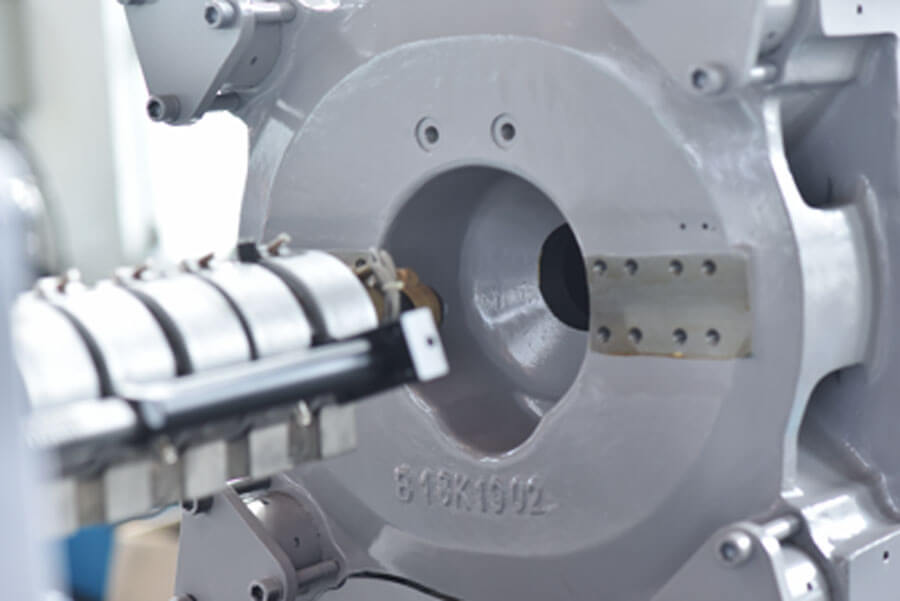

Specialty-developed IPM servomotor with fast response, large torque, low noise and mild temperature profile

Euromap-style ejector support, wide applicability for different moulds

Centralised automatic lubrication system.

No manual control needed. No mistakes.

No wastage. Fit for clean-room environments

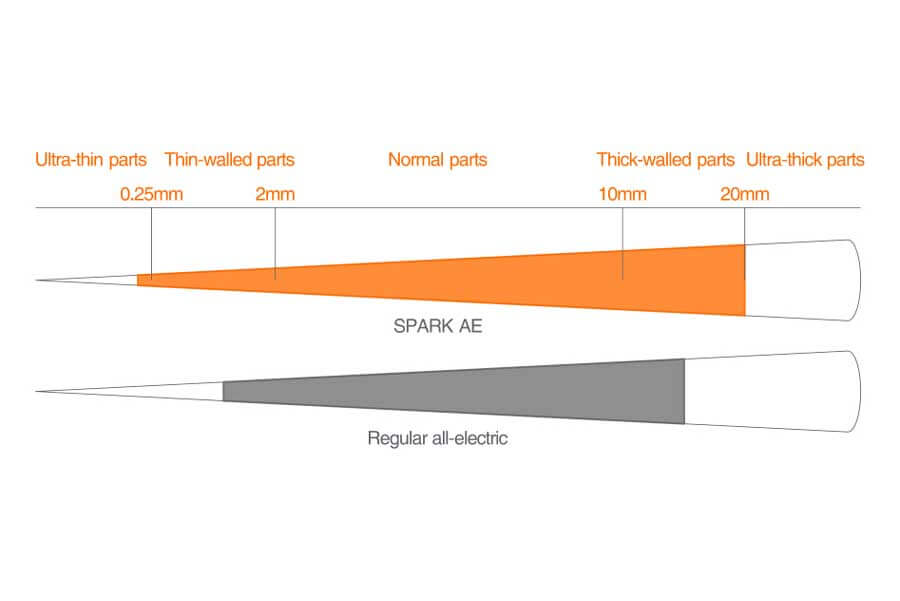

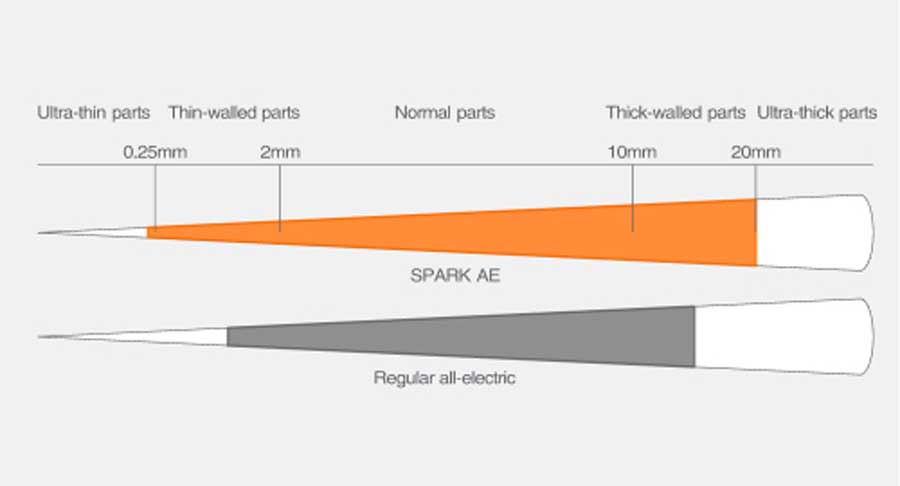

faster dry cycle time than competition offerings due to SPARK AE’s highly responsive advanced servosystem.

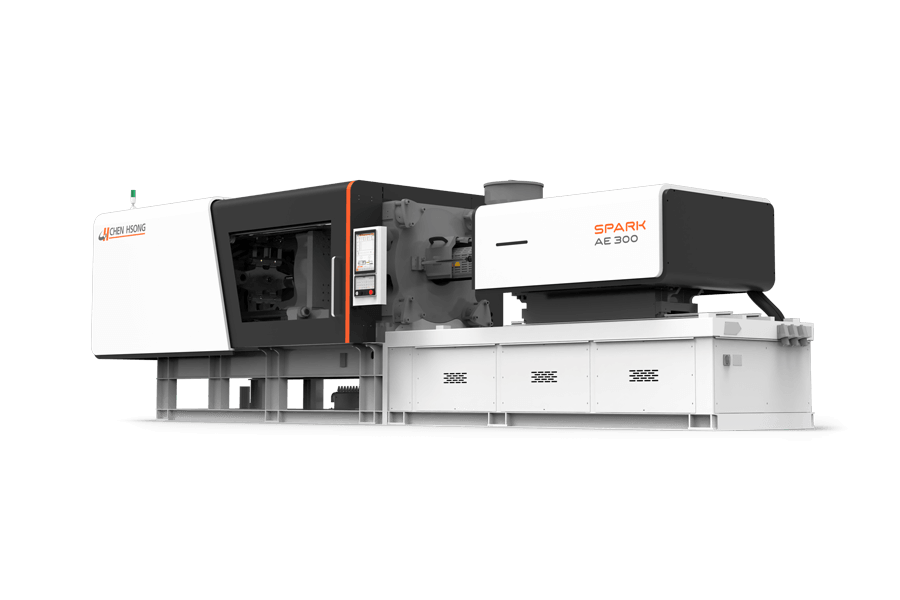

Redefining The Benchmark For Low Energy Consumption,

Actual Comparison:

SPARK AE300

0.23kWh/kg

Regular 300T all-electric

0.29kWh/kg

We value your feedback! If you have a specific question or inquiry, or just want to let us know how we are doing, please complete the form below. We’ll get back to you as soon as possible.

Stay in touch and get the latest from CH India. Stay informed with product updates, launches, news, trade shows and much more.

North:

New Delhi

Ghaziabad

Gurgaon

Rajasthan/Bhiwadi

West:

Navi Mumbai

Mumbai

Bhosari

Chakan

Maharashtra/Aurangabad

South:

Tamil Nadu / Chennai

Tamil Nadu/ Coimbatore

Karnataka /Bengaluru

Tamil Nadu / Hosur

Choose Your Region

The Chen Hsong Group has offices and distributors all around the globe.

Select your region from below or search our global list of distributors.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

|

|

Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |