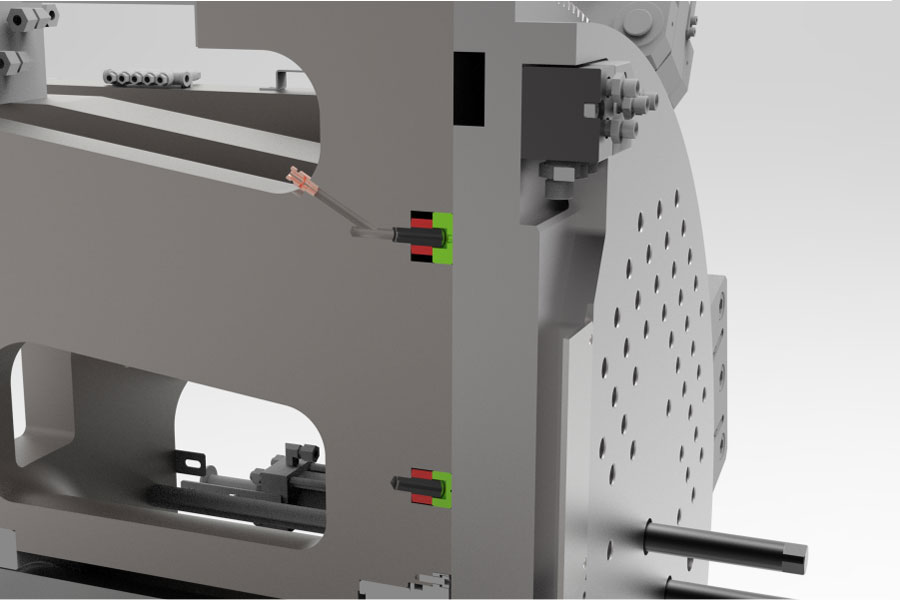

Real-time dynamic adjustments- exceptional control over multi-material molding operations

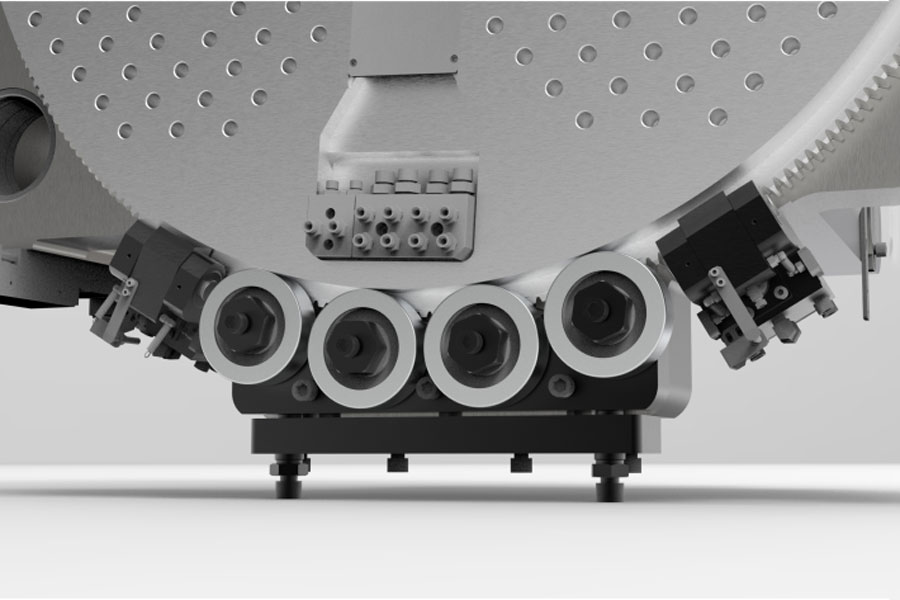

CAN bus expandability and Multi mode for easy equipment connection and varied injection modes.

Ultra-fast CPU scan time and precise temperature control for the most demanding manufacturing conditions

The DM III is EtherCAT-compliant, ensuring seamless integration within existing industrial automation systems.

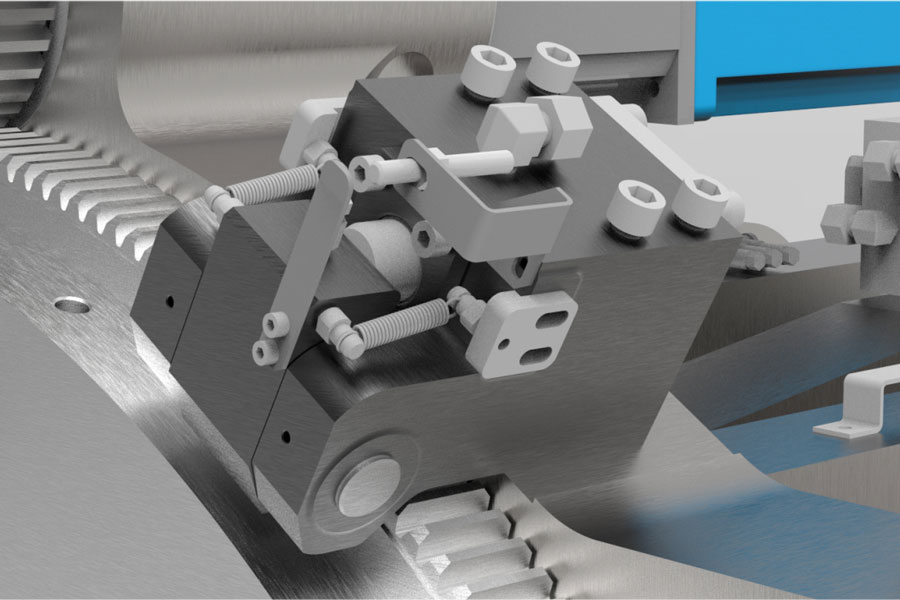

High-precision Injection Control Enabled By Ether Cat Control Bus

We value your feedback! If you have a specific question or inquiry, or just want to let us know how we are doing, please complete the form below. We’ll get back to you as soon as possible.

Stay in touch and get the latest from CH India. Stay informed with product updates, launches, news, trade shows and much more.

North:

New Delhi

Ghaziabad

Gurgaon

Rajasthan/Bhiwadi

West:

Navi Mumbai

Mumbai

Bhosari

Chakan

Maharashtra/Aurangabad

South:

Tamil Nadu / Chennai

Tamil Nadu/ Coimbatore

Karnataka /Bengaluru

Tamil Nadu / Hosur

Choose Your Region

The Chen Hsong Group has offices and distributors all around the globe.

Select your region from below or search our global list of distributors.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

|

|

Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |