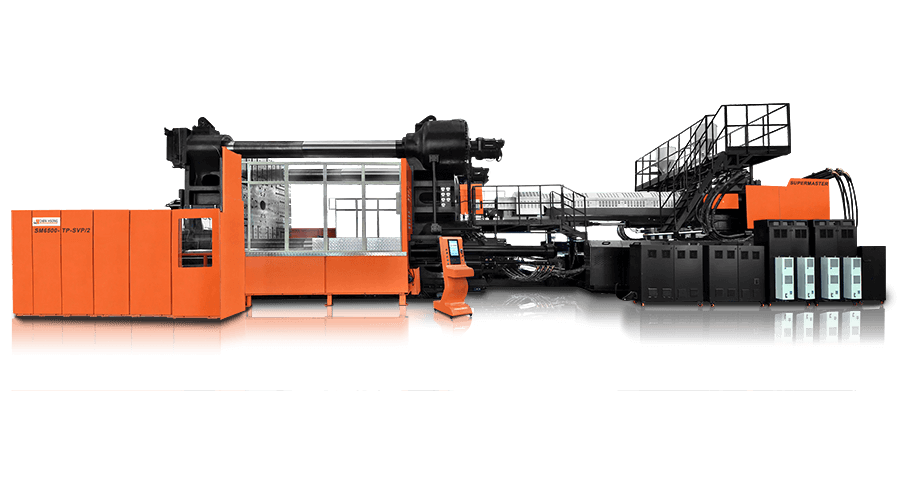

The SUPERMASTER-Series is a revolutionary “true” two-platen design from the Chen Hsong Group. Designed in 3 years with a team led by leading Europe and Japanese industry experts, it represent a unique ccombination of world-class, no ompromise performance and characteristic Chen Hsong affordabilty. Numerous innovations protected by international patents give this machine a price-performance value that is previously undreamt-of.

Hundreds of presses from the SM700 up to SM6500 tons are currently running reliably for customers around the world in every industry.

They deliver high precision, high stability, high speed, and ultimate mould protection without any of the traditional compromises.

The MPC 7.0 is a high performance, new generation intelligent computer controller available exclusively from Chen Hsong. Designed in Japan and constructed with the latest SMT technology, it boasts full compatibility with JIS standards, enhanced stability and ultimate relliability. This controller comes standard with multi-lingual interfaces, built-in networking, advanced intelligent diagnostics, and the ability to retain data for over five years without external power. Includes full networking support for industrie 4.0.

We value your feedback! If you have a specific question or inquiry, or just want to let us know how we are doing, please complete the form below. We’ll get back to you as soon as possible.

Stay in touch and get the latest from CH India. Stay informed with product updates, launches, news, trade shows and much more.

North:

New Delhi

Ghaziabad

Gurgaon

Rajasthan/Bhiwadi

West:

Navi Mumbai

Mumbai

Bhosari

Chakan

Maharashtra/Aurangabad

South:

Tamil Nadu / Chennai

Tamil Nadu/ Coimbatore

Karnataka /Bengaluru

Tamil Nadu / Hosur

Choose Your Region

The Chen Hsong Group has offices and distributors all around the globe.

Select your region from below or search our global list of distributors.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

|

|

Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |